Development technologies

Having passed the stage of 3D modeling, the idea turns into a virtual model of the product and is tested for the operating conditions on a computer, and then goes to the stage of implementation. To do this, we use the technology of growing a prototype on our own 3D printer, which can take from 2 hours to 3 days, depending on the complexity of the model. Starting from this stage, the future product is already being tested in the test center.

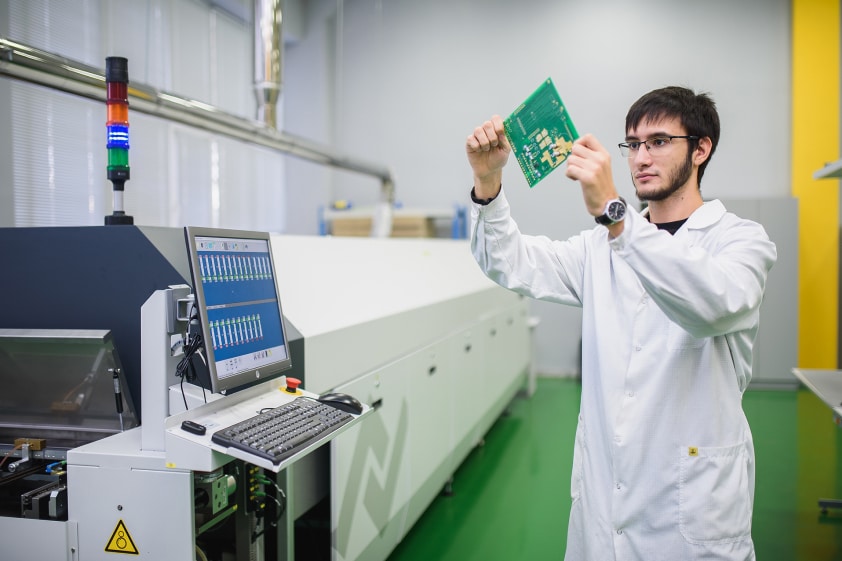

For the production of sample parts, we use silicone molds, we use an automated plastic molding workshop and a metal case production workshop, and for the pilot production of printed circuit boards we use a small SMD assembly line.

The use of these technologies allows us to quickly assemble a model of the future product. Experimental batches undergo a full cycle of tests at the Teas equipment center in order to confirm the laid down technical characteristics.